Electromagnetic Induction: Shocking New Way to Boost Taste and Longevity of Beverages?

Is this the future of preserving beverages like beer and milk?

Developed by Induction Food Systems(IFS), an affiliate of Purdue University, a new electromagnetic induction technology could change how we apply heat to liquids to improve shelf life and retain flavor (pasteurization). For industries like beer and milk, this could be a revolutionary, new advancement because of just how much more efficient this new system is. However, before delving into the positives of IFS' new system, let's examine how many of our favorite beverages are pasteurized.

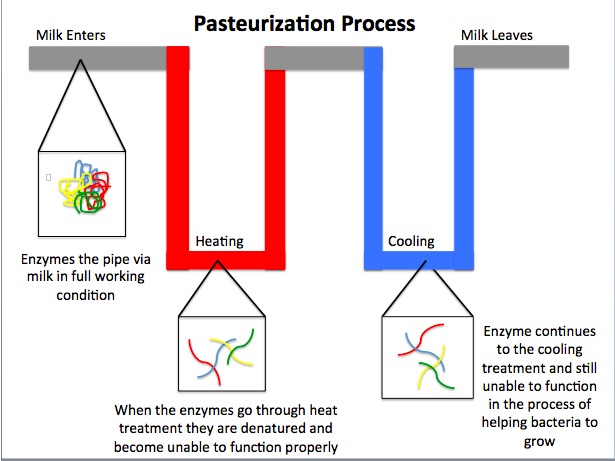

Pasteurization

Pasteurization is the process by which many beverages are made safe to consume. The basic premise is that mild heat (usually less than 100 degrees Celsius) is applied to beverages in short bursts, or consistently, to eliminate pathogens and prolong shelf life. Shelf life is prolonged as pasteurization effectively kills or deactivates bacteria and enzymes that could contribute to accelerated spoilage or contamination. Many beverages are heated a second time in a process known as double pasteurization to ensure the complete elimination of any potential contaminants.

The Problem with Current Pasteurization Methods

The current method that most people use to pasteurize their beverages is steam-based, which is tricky to control effectively in terms of temperature consistency. This downside leads to several problems, chief among these is a loss of aroma and flavor in pasteurized beverages. In addition, [1] "In addition, steam is inefficient, slow, and costly in terms of energy." Add to that the fact that pasteurization is also responsible for reducing the amount of vitamins and minerals in beverages, and it's clear that a new method is required.

The New Method

The new method replaces steam with electromagnetic induction. It works when [2] "an external coil connected to a solid-state electronics pack generates high-frequency radio waves that heat an induction element embedded in a section of pipe. This, in turn, heats the beer or other product as it passes through the pipe." Already, after preliminary testing, IFS' new system seems to be a huge step in the right direction. [3] "The new process is not only scalable and easy to install, but also provides 600 percent more precise temperature control, is three to five times more energy efficient, heats 24 times faster, and requires an 80 percent smaller footprint than a steam plant."

You can check out how the new IFS pasteurization process works in the video below.

How it Works -- Induction Food Systems from Induction Food Systems on Vimeo.